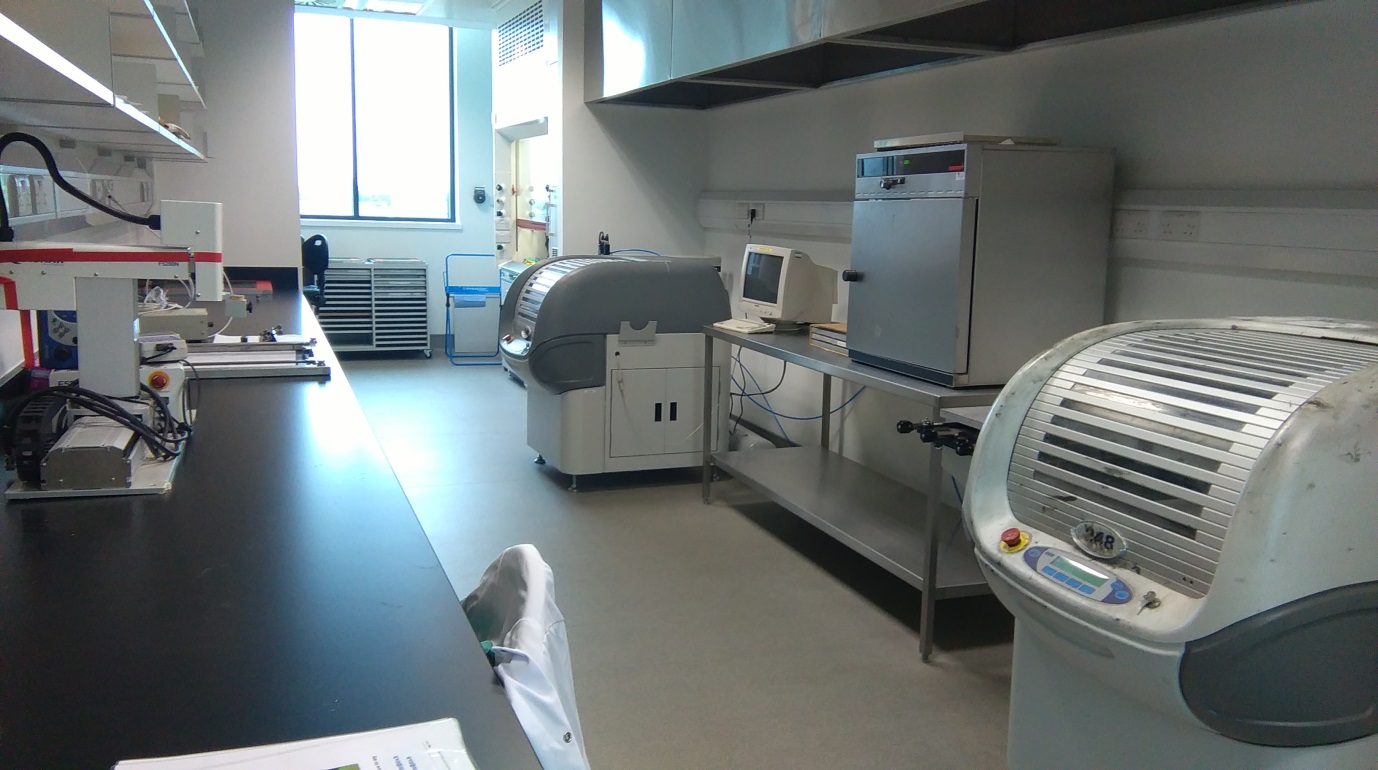

Screen Printing Lab

The screen printer is a materials deposition tool, used for thick film printing of tailored ink formulations. Typical uses for this facility include printed electronics or electronic circuitry fabrication and electrode fabrication. Graphics printing can also be done. A range of substrates can be used as the deposition medium including rigid and flexible plastics, ceramics, paper and textile materials. The facility also includes a UV curing system and a thermal curing oven.

DEK Screen Printing |

|

DEK / 248

Dek 248 manual / semi-automatic printer with imaging system (SP1)

Dek 248 manual / semi-automatic printer (SP2)

The DEK-248 screen printer offers a method of fabricating unique electrode designs quickly and reliable. The Two DEK-248 systems housed in the NRF offer screen printing over 200 x 200 mm and 400 x 400 mm areas giving flexibility to the users in design type and electrode number per screen. Both systems are equipped with 400 mm and 200 mm squeegee and flood blades, print speed of 10 – 70 mm/sec and squeegee pressure of 0 – 15 kg. The NRF Screen Printing Facility also offers thermal and UV curing capabilities. A Memmert convection oven with time controlled temperature cycles and a UVPS UV curer with high through put are available on site.

- Screen Frame Size: 508mm x 508mm

- Print Speed: 10-70mm/sec

- Squeegee Pressure: 0-15 kg

- Menu Storage: 35 programs

- Print Area: 432mm x 405.5mm

- Maximum Substrate Size: 500mm x 450mm

- Minimum Substrate Size: 100mm x 50mm

- Board Thickness: 0.5mm to 5.0mm

|

Prices

Academic: €10 /hr

Industry: € On Request

Technical Contact Stephen Fuller

|

|